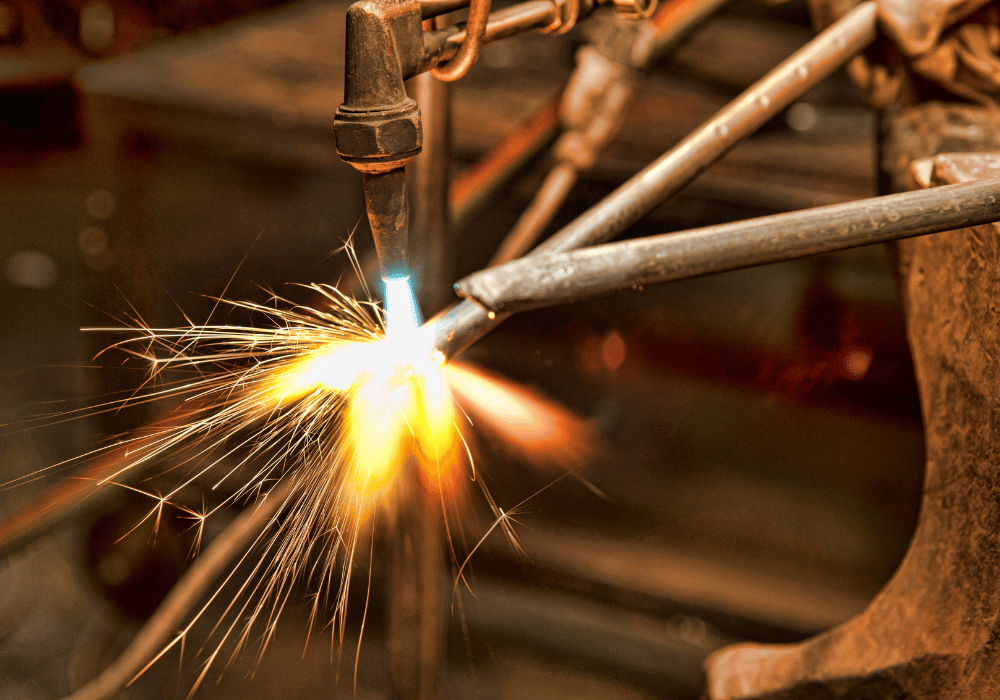

Product prototyping is an essential part of the manufacturing process. Whether you are introducing a new product or upgrading an existing one, prototyping helps to determine the design’s feasibility and functionality before it goes to production. The prototyping process can be complex and time-consuming, especially when dealing with metal products. However, with the help of metal fabrication, product prototyping can be made more efficient and cost-effective. In this post, we’ll delve into how metal fabrication can improve product prototyping.

Flexible Fabrication Designing

Flexible Fabrication Designing

Metal fabrication provides manufacturers with the flexibility to design and modify products to meet specific requirements. With metal fabrication, manufacturers can work on different types of metal, like steel, aluminum, and copper, among others. In addition, manufacturers can modify existing designs without starting the prototyping process from scratch. This flexibility ensures that manufacturers can make changes to the design rapidly, which saves time and money.

Precise and Consistent Prototyping

When it comes to product prototyping, precision is critical in ensuring a functional final product. The metal fabrication process uses advanced technology to produce products with precision and consistency. Indeed, precision is crucial for prototypes that require a high degree of accuracy, and metal fabrication guarantees this.

Early Detection of Design Flaws

Product prototyping detects design flaws early in the design phase, before production. Early detection saves production costs and reduces lead time. With metal fabrication, manufacturers can prototype metal products accurately and quickly, which enhances the prototyping and testing process.

Faster Time to Market

Faster Time to Market

The speed at which manufacturers can convert an idea into a final product is crucial to business success. With metal fabrication, manufacturers can achieve the speed they need to bring products to market faster. The metal fabrication process allows manufacturers to build specific designs and modifications quickly. This speed reduces the production cycle, leading to faster time-to-market, which ultimately benefits the manufacturer.

Custom Metal Fabrication Reduces Waste

The manufacturing process can be wasteful, and prototyping is no different. However, metal fabrication can reduce waste during the prototyping phase. Typically, metal fabrication processes rely on computer-aided design (CAD) systems, which minimize material wastage. Manufacturers have greater control over the assembly processes and take greater care in using available materials, resulting in less wastage.

Custom metal fabrication has revolutionized the prototyping process, allowing manufacturers to optimize their products better, faster, and more cost-effectively. The benefits of metal fabrication are numerous, and they positively affect all aspects of the manufacturing process. By using metal fabrication for prototyping, manufacturers can develop better-quality products in a cost-effective, streamlined manner.