Metal fabrication, a cornerstone of modern engineering, has undergone significant transformation over centuries. From forging and casting in ancient times to sophisticated computer-aided manufacturing today, the evolution of metal fabrication techniques has been pivotal in shaping industries and advancing technology. Melnik Custom Metal Fabrication, a leader in the metal fabrication industry, takes you through a journey of how these techniques have evolved and continue to impact modern engineering.

The Beginnings of Metal Fabrication

Historically, metal fabrication was limited to manual techniques such as hammering, forging, and casting, relying heavily on the skill and strength of the craftsman. These processes laid the groundwork for the development of tools and machinery, enabling the construction of everything from weapons and armor to architectural structures.

The Industrial Revolution: A Turning Point

The Industrial Revolution marked a significant turning point in metal fabrication. The introduction of steam power and mechanization led to the development of rolling mills, lathes, and drilling machines, drastically increasing production capabilities and precision. This period also saw the birth of assembly line manufacturing, revolutionizing the way products were made and contributing to mass production.

The Advent of Welding and Cutting Technologies

The 20th century introduced welding and cutting technologies, such as oxy-fuel cutting and electric arc welding, further expanding the possibilities of metal fabrication. These techniques allowed for stronger and more intricate assemblies, paving the way for advancements in construction, automotive, and aerospace industries.

Precision Engineering with CNC Machining

The advent of Computer Numerical Control (CNC) machining in the latter half of the 20th century marked a new era in metal fabrication. CNC technology enabled the precise and automated control of machining tools, allowing for highly accurate and repeatable production processes. This innovation significantly reduced the margin for error and opened up new possibilities for complex designs and tight tolerances.

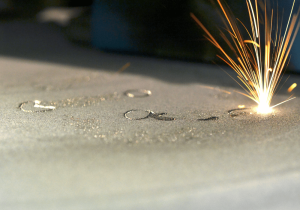

The Digital Age and Beyond: 3D Printing and Laser Cutting

Today, metal fabrication continues to evolve with the integration of digital technologies. 3D printing, or additive manufacturing, allows for the creation of components by adding material layer by layer, offering unparalleled design flexibility and efficiency. Laser cutting, with its high precision and speed, has become a staple in modern fabrication shops, capable of cutting intricate designs in a fraction of the time of traditional methods.

The Future of Metal Fabrication

As we look to the future, the metal fabrication industry is set to embrace further advancements, including automation, robotics, and artificial intelligence (AI). These technologies promise to enhance efficiency, reduce waste, and open up new frontiers in engineering and design.